Installation instruction book

First of all thank you to purchase and use our products, I hope our products can bring you the convenience and comfort.

Before using this unit, please read this manual. So that you can safe, correct operation and maintenance, and makes the machine has long maintained good working state.

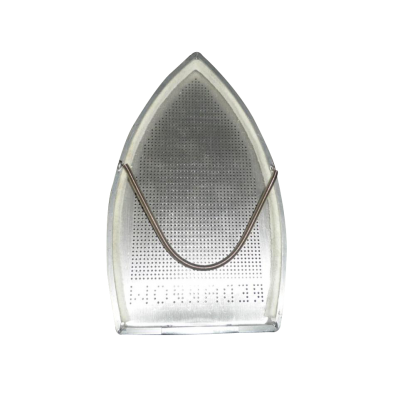

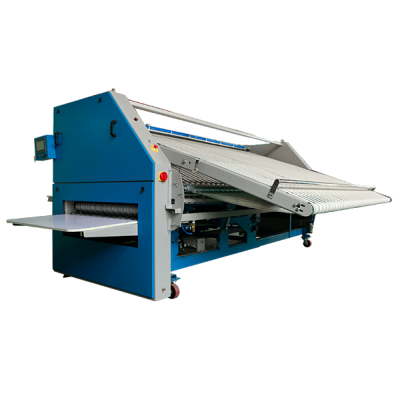

- It has both suction and air blowing functions, the clothes can be adsorbed on the hot mold or table top, the moisture and steam in the clothes can be extracted to cool and dry quickly, save energy.

- It has an small inner automatic steam generator, which does not require any external steam source during work.

- It’s equipped with a high-speed motor, which has strong suction wind and fast dehumidification.

- It can be used as a spotting table with jet gun, the steam volume from the jet gun can be adjusted according to the needs, improve the efficiency.

- Equipped with work light, reasonable structure, conveniently for operation.

- Main technical parameters:

|

Specification

|

Unit

|

Value

|

|

Voltage

|

V

|

220/380

|

|

Breeze pressure

|

Pa

|

≤-150

|

|

Noise

|

dB

|

≤72

|

|

Power

|

W

|

750

|

|

Pump power

|

W

|

250

|

|

Heating power

|

KW

|

3

|

|

Rated evaporation

|

KG

|

4.3

|

|

Rated steam pressure

|

MPa

|

0.4

|

|

Steam temprerature

|

℃

|

151

|

|

Effictive water volume

|

L

|

15

|

|

Dimension

|

mm

|

1700×500×1930

|

|

Weight

|

KG

|

180

|

- Open the package to install the compoents into a complete machine, and put the machine in a stable position;

- Connect the grounding protection wire on the outer casing;

- Check the external power supply voltage before plug in;

- Connect the air pipe on the platform to the external air source, and check whether the external air supply is normal. Close the drain valve.

- Fill the water tank before start the machine, check if there is any air in the water pump and discharge it;

- Turn on the power main switch and air source button on the control panel. The water pump starts to supply water to the generator. When the water level reaches the working level, stop adding water and start heating;

- When the steam pressure in the generator reaches 0.32MPa-0.4MPa, available to start ironing. At this time, press the suction(blowing) button on the control panel to continue working, or step on the pedal halfway to perform the suction, fully step on for blowing operation.

- Power and air supply should be cut off after working.

- Be sure to connect the grounding protection wire before using, to ensure the safety of the staff;

- Open the rear panel of the machine regularly, remove the dirt on the wind wheel and damper slide, better to apply lubricant to the damper slide regularly;

- If the pressure guage indication rises to 0.4MPa 1 to 2 minutes after starting the generator, it’s caused by the volume expansion of the water in the generator after heating. This phenomenon can be eliminated by opening the exhaust valve and then close it again.

- When the steam generator pressure does not reach the working pressure(0.32MPa-0.4MPa), the steam iron and jet gun cannot be used;

- It is suitable for using purified water, otherwise it will affect the service life of the pot body, electric heating tube and other parts;

- After using the machine for three months, the electric heating tube and water level probe should be disassembled, to remove the scale(depending on local water quality) to ensure steam production, component sensitivity and steam purity;

- After the daily using, drain the remaining water and keep the pot clean;

- If you need to repair or replace parts, it should be turned off the power supply, drain the steam in the generator, and never put pressure on the parts;

- The service life of the generator in this machine is 5 years, it will be scrapped after the time limit;

10. The insulation resistance between the charged and uncharged bodies in the

cold state should be greater than 2 megohms. After using it for a period of time, it should be detected in time;

11. If you are not ready to use the machine for a long time, please fill the pot with water and close all valves to prevent corrosion of the furnace;

12. To ensure the ironing effect, the tablecloth and sponge on the rock arm should be cleaned or replaced frequently.

- Common malfunction and Solution:

|

Malfunction

|

Cause of issue

|

Solution

|

|

The motor doesn’t

work after turn on

|

- Poor power

connection

- Switch damaged

3.Motor damaged

|

1.Check the circuit

2.Replace

3.Replace

|

|

The motor is Working

without wind function

|

1.Air duct blocked

2.Tablecloth and sponge

blocked

|

1.Clear the blockage

2.Clean or replace

|

|

The motor is work but

only wind sucks or blows

|

1.Blow(suction)wind switch damaged

2.The lubricat on the wind tunnel is dry

3.Pneumatic component

solenoid valve or

cylinder damaged

|

1.Replace

2.Remove dried

lubricant and

reapply

3.Replace

|

|

Small air volume

|

- Fan reverse

- Duct damaged

- Cylinder

|

- Adjust the steering

- Replace

- Adjust the cylinder

and check the air

supply pressure

|

|

Fan no working

|

- Wind wheel is stuck

- Contactor is damaged

- The pedal is damaged

- Motor is damaged

|

- Adjust the wind wheel

- Replace

- Replace

- Repair or replace

|

|

The electric heating tube does not work after the generator is started

|

- Poor power supply

contact

- Electric heating tube

is damaged

3.AC contactor burned out

4.Water is not added to the set level

|

1.Check circuit

2.Replace

3.Repalce

4.Keep fill water to the set level

|

|

The pressure doesn’t rise for a long time

|

- Heat pipe is damaged

- Heating contact is

damaged

|

- Replace

- Replace

|

|

The electric heating tube can’t stop

working when the

pressure gauge

indicates that it

has exceeded 0.4MPa

|

1.The pressure controller is failure

|

1.Replace

|

|

AC contactor keeps

jumping back and

forth

|

1.The voltage below 200V

2.The pressure controller is failure

|

1.Install the regulator

2.Replace

|

-2-400x400.jpg)

-400x400.jpg)